Curious about RFID and whether it belongs in your warehouse? Here’s what you need to know.

What is RFID and How Does It Work?

Radio Frequency Identification (RFID) is a wireless tracking technology that uses electromagnetic fields to identify and monitor tagged objects automatically. Unlike traditional barcodes, which require line-of-sight scanning, RFID allows items to be scanned without direct visibility — sometimes even in bulk.

An RFID system typically includes:

- RFID tags (attached to products or pallets) that contain electronically stored information

- RFID readers and antennas that transmit and receive radio signals

- Software and infrastructure that connect the system to a central database or ERP

There are two main types of RFID tags:

- Passive tags, which are powered by the reader’s signal and are generally less expensive

- Active tags, which contain their own power source and are used for long-range or high-value tracking

RFID is widely used in industries where speed, volume, and accuracy are critical — such as automotive, aerospace, and large-scale retail logistics. But while the technology is impressive, its real-world application depends heavily on warehouse size, complexity, and operational needs.

Key Benefits of RFID Technology

RFID offers a number of potential advantages, especially in environments where inventory management is a large-scale, high-stakes operation:

- Faster Scanning: RFID readers can scan multiple tags at once without requiring visual alignment — making receiving, cycle counts, and shipping more efficient in high-volume settings.

- Improved Inventory Accuracy: By automating data collection and reducing human error, RFID can help maintain more accurate inventory records.

- Enhanced Visibility: Some systems allow real-time location tracking of inventory, assets, or equipment — beneficial for complex warehouse networks.

- Non-Contact Operation: Unlike barcodes, RFID doesn’t require scanning each item individually, which can save significant time in large operations.

These benefits can translate into improved operational efficiency, reduced labor, and better decision-making — but only when the system is fully integrated and the volume justifies the investment.

Challenges and Costs to Consider

While RFID technology offers impressive advantages, it comes with a set of challenges that make it less practical for many small and mid-sized distributors — especially in the convenience distribution space.

Here are some of the common barriers:

- High Upfront Costs: RFID tags, readers, antennas, and supporting infrastructure can be expensive to purchase and install. Passive tags are cheaper, but outfitting thousands of SKUs can still add up quickly. Active tags, which offer extended range, are even more costly.

- Complex Implementation: Integrating RFID with your existing ERP and warehouse systems takes careful planning, technical expertise, and often custom development. It’s not a plug-and-play solution.

- Training and Change Management: Teams need training to adapt to new workflows. Without proper implementation and support, the benefits of RFID can be lost to confusion or resistance.

- Environmental Limitations: Metal surfaces, liquids, and certain packaging materials can interfere with RFID signals, potentially reducing reliability.

Because of these factors, RFID is typically adopted by large-scale operations where the speed and automation gains outweigh the upfront investment and complexity.

RFID vs. Barcode Technology: A Quick Comparison

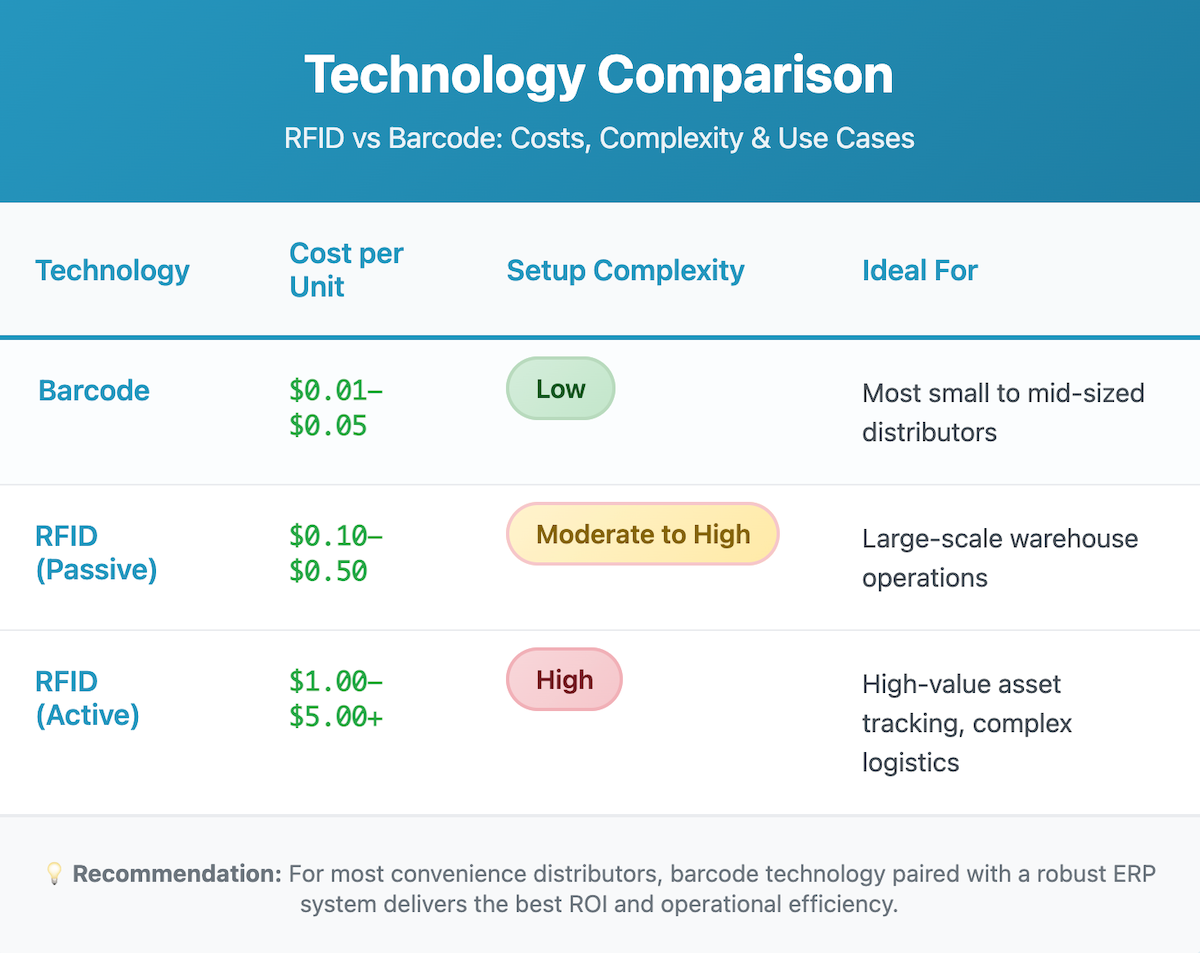

To help you weigh your options, here’s a quick comparison of barcode and RFID technologies based on cost, complexity, and ideal use cases:

Why RFID May Not Be Right for Most Convenience Distributors

For convenience distributors, the challenges of RFID often outweigh the benefits. Most operate with relatively lean teams, serve a focused range of SKUs, and rely on quick, repeatable processes — all of which are already well-supported by traditional barcode scanning and a strong ERP system.

Here’s why RFID may not deliver the ROI you’d expect:

- You’re Already Fast and Accurate: When paired with DAC ERP and barcode scanning, most CDR Software customers already achieve high inventory accuracy and efficiency without needing to overhaul their systems.

- Cost Doesn’t Justify the Benefit: The price of tags, readers, and infrastructure can quickly outpace the operational gains in smaller or less complex warehouses.

- Barcode Systems Are Reliable and Proven: In the hands of a well-trained team using the right ERP tools, barcodes continue to offer a simple, scalable, and cost-effective way to manage inventory.

RFID may sound cutting-edge, but that doesn’t mean it’s the right tool for every job. For most convenience distributors, the smarter move is to optimize the technology you already have — and ensure it’s tightly integrated with your ERP for maximum efficiency.

What’s the Alternative? Reliable Inventory Tracking with DAC ERP

RFID isn’t the only path to accurate, efficient inventory management — and for most convenience distributors, it’s not the most practical one. That’s why CDR Software focuses on providing the tools that deliver real value without unnecessary complexity or cost.

DAC ERP gives you everything you need to maintain tight control over inventory using proven, cost-effective technology:

- Integrated barcode scanning to streamline receiving, picking, and cycle counting

- Real-time inventory visibility across your warehouse operations

- Accurate data entry and tracking that reduce manual errors

- Built-in tools for forecasting, replenishment, and reporting

With DAC ERP, you don’t need an expensive RFID overhaul to improve accuracy and efficiency. Our solution is designed specifically for convenience distributors — meaning you get the features you need without the bloat or barriers of large-scale systems.

Conclusion: Stay Informed, But Invest Wisely

RFID is a powerful technology with real benefits in the right context — but for most convenience distributors, it’s an expensive and unnecessary upgrade. While it offers speed and automation for large-scale warehouses, the investment doesn’t always make sense for smaller operations where barcoding and a strong ERP already get the job done.

At CDR Software, we believe in helping our customers stay competitive by investing in the right tools — the ones that deliver clear ROI and fit the realities of your operation.

Want to streamline your inventory management without overcomplicating your tech stack?

Contact us today to learn how DAC ERP helps convenience distributors like you achieve accuracy, efficiency, and control.

FAQ: RFID in Warehouse Inventory Management

What is the difference between RFID and barcoding in inventory management?

RFID uses radio frequency signals to identify and track items, allowing bulk scanning without direct line of sight. Barcoding requires a scanner to visually read each barcode individually. While RFID offers speed and automation, barcoding remains more cost-effective and widely used — especially in smaller warehouse operations.

Is RFID more accurate than barcodes?

RFID can reduce manual scanning errors and provide faster updates, which can lead to improved accuracy in high-volume environments. However, barcoding, when paired with a well-integrated ERP system like DAC ERP, also delivers highly accurate inventory tracking at a much lower cost.

Why isn’t RFID used in all warehouses?

The cost of RFID hardware, infrastructure, and integration makes it less practical for many small to mid-sized warehouses. RFID is often best suited for large operations managing high-value or high-volume items. Simpler barcode-based systems provide better ROI for many businesses.

What does RFID cost to implement in a warehouse?

Costs vary depending on the size and complexity of the operation, but expenses include RFID tags, readers, antennas, network setup, software integration, and staff training. Passive tags may cost $0.10–$0.50 each, while active tags can cost several dollars — not including system-wide infrastructure.

Can ERP systems work without RFID?

Absolutely. Many ERP systems, including DAC ERP, are designed to work seamlessly with barcode technology and manual inputs. These systems provide real-time inventory visibility, accurate tracking, and operational efficiency — all without requiring RFID.

Related:

https://cdrsoftware.com/blog/rf-scanning-in-modern-distribution-models/

https://cdrsoftware.com/blog/impact-of-rf-scanning-systems/

https://cdrsoftware.com/blog/rf-scanning-technology-in-distribution/